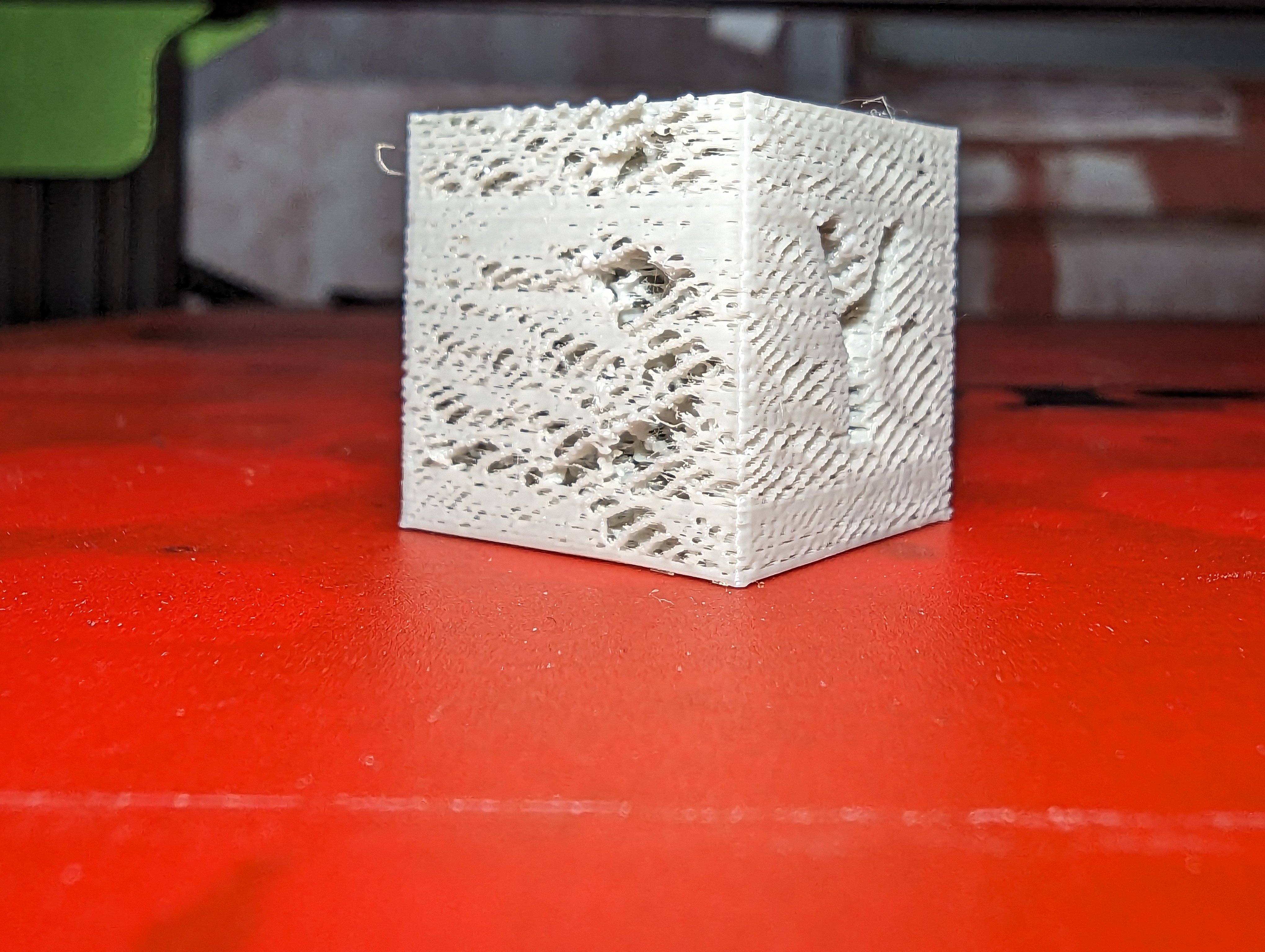

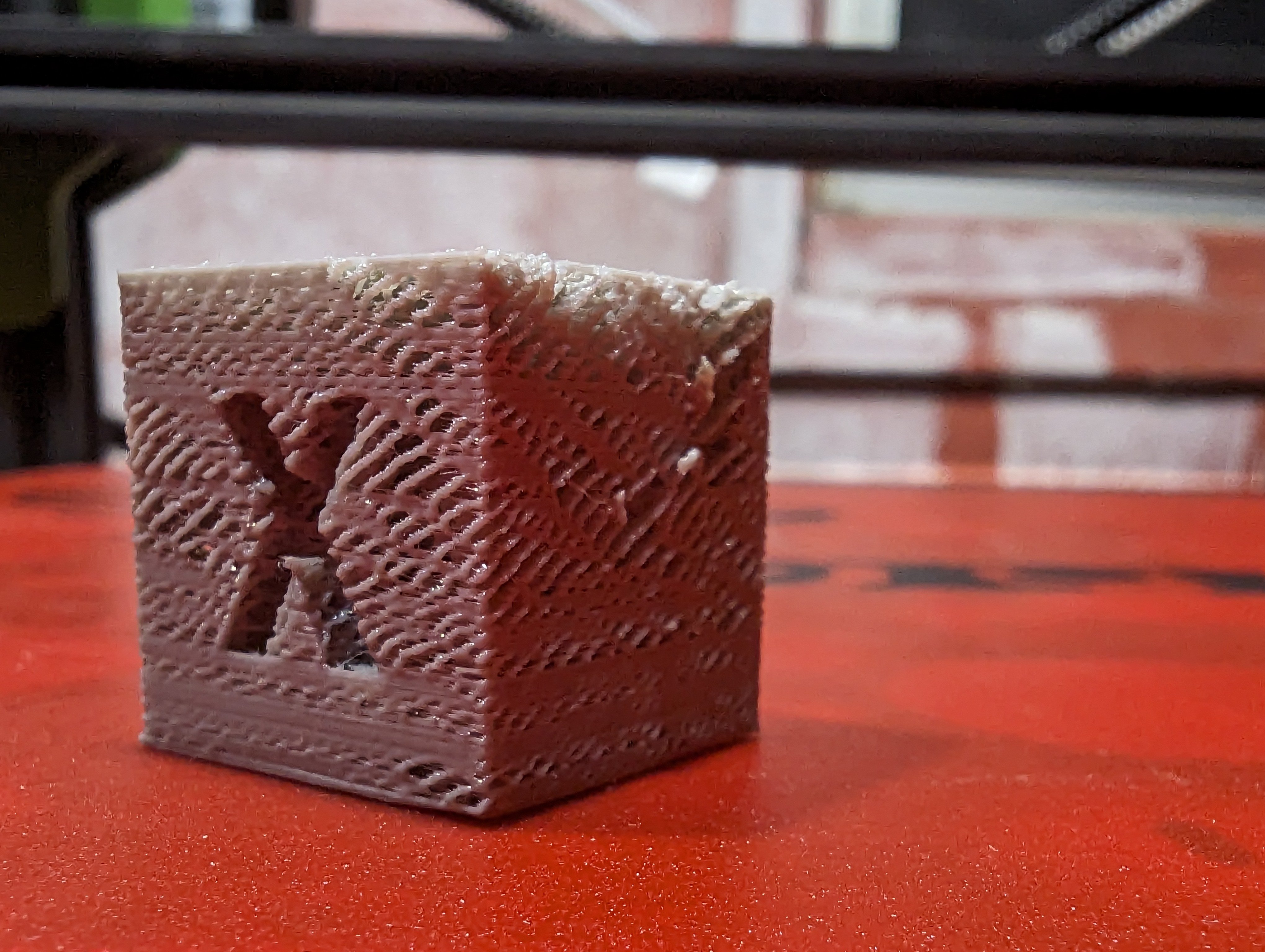

Hi everyone, I’m extremely new to 3d printing, and have taken over a printer from a friend who doesn’t use his. I’m trying to get those smooth prints I see people having, and I understand I need to get a smaller layer height to achieve the details. However my stuff keeps coming out looking like the pictures below.

Any idea what’s going on and how I can start fixing it?

I’m printing PLA filament.

- Nozzle temp: 215

- bed temp:70

- nozzle size: 0.3mm

- Layer height: 0.1mm

Thank you!

There are multiple potential issues. It is hard to say where to start. The little solid band in the bottom pic, below the X, hints at an issue with an obstruction in the nozzle.

The repetition in the outer wall pattern hints at an issue with the extruder gears. Any time you see a pattern like this, it relates to the extruder mechanics. This could be any number of issues like too much or too little tension on the filament at the extruder feed gear. It could be cracked or worn out parts. It could be a worn out or bad gear or idler. The actual extruder mechanism is a high precision ~0.01mm class system. Any error here is a big problem.

It looks like you just placed these on a print bed for pictures. If these are how they were printed, your first layer height is too high. Maybe it is just the lighting, but if the top is more sparse than the rest of the print, I think you need to calibrate your flow rate steps per millimeter.

Underextrusion. You probably have burnt filament clogging your nozzle. Get your nozzle to 80C, then set it to 150C and start pulling the filament back out as the temperature climbs. It’s called a cold pull and usually clears this sort of thing.

Set your initial builtplate temp to 70, and the builtplate temp to 55 for printing. At 70 the pla will hit glass transition, then when it cools to 55 the adherence will be very good.

If you want smooth walls, slow the speed to like 40mmps, and squish the layers down to 0.10 mm with a .4mm nozzle if you can.

Play with ironing for the top surface smoothing.

I don’t recommend reducing your cooling much with pla. Maybe down to like 50% at the lowest.

Edit: your nozzle and later height should be fine, I glossed over that. Bring the nozzle down to 200 or so.

To add to this, I would highly recommend not worrying about using a .10mm layer height until you have reliable prints at .20mm height.

Trying to get finer detail is just compounding issues onto a print that looks to have quite a few things wrong.

I agree with you on underextruding. Easiest way to test would be for OP to measure 150mm of filament from the entrance of the extruder and mark it. Set nozzle temp to 215 or so, and manually extrude 100mm. Then re-measure to your mark and see how far off you are. If it’s way off OP needs to calibrate his extruder motor steps.

Also as other people have said, might be worth trying a different filament, especially if that filament is really old.

I am pretty new to fdm, but is it possible that you are using a high temperature and low cooling? Another possibility is the filament is too wet and need to be dried. Thinking about it, wet filament is a higher possibility.

Also you can try increasing the flow rate or if it’s not possible slowing the speed. It may be under extruding.

A couple things if you’re new-ish:

First, I would highly recommend using a 0.4 nozzle. That’s the standard size most people will assume you’re using and it will just make your life easier.

Second, start with a 0.2mm layer height and adjust down in steps of 0.04. Below 0.12mm can bring in more compounding problems related to the filament itself.In short, tune for the defaults first, then adjust.

It might just be sliced for a 0.4 nozzle (default). If you downloaded the gcode file, that’s probably it. Run the stl or 3mf through your slicer software, making sure the extruder size is 0.3mm.

For some reason, I’m having trouble getting a sense of the depth of those strands and holes. If you hold it, does the surface feel scratchy and rough, or bumpy and smooth?

What adjustment have you made to the machine? Did you recently change to that 0.3mm nozzle?

Are you sure it’s PLA and not other flavor, like PLA Pro, PLA+, etc.?Alright so first big thing, if you’re using Cura make sure it’s set to a filament diameter of 1.75mm. If memory serves it still defaults to 3mm.

That can cause serious under extrusion problems that you’ll be chasing forever until it’s fixed.

Also what speed are you printing at, what printer are you using, and what slicer?

Have you done a test print while watching it and listening?

It looks like under extrusion but it’s hard to say if it’s an obstruction, poor gear contact, or steps.

I would watch and listen to a print for a while and see if it’s making any clicking or snapping sounds. That could be a good indicator of something wrong with the extruding part.